Detect Surface Discontinuities in Both Ferromagnetic and Non-ferromagnetic Materials

Liquid Penetrant Inspection is one of the most widely used NDE/ NDT methods. It’s popularity can be attributed to two main factors: its relative ease of use and its flexibility. Liquid Penetrant Inspection can be used to inspect almost any material.

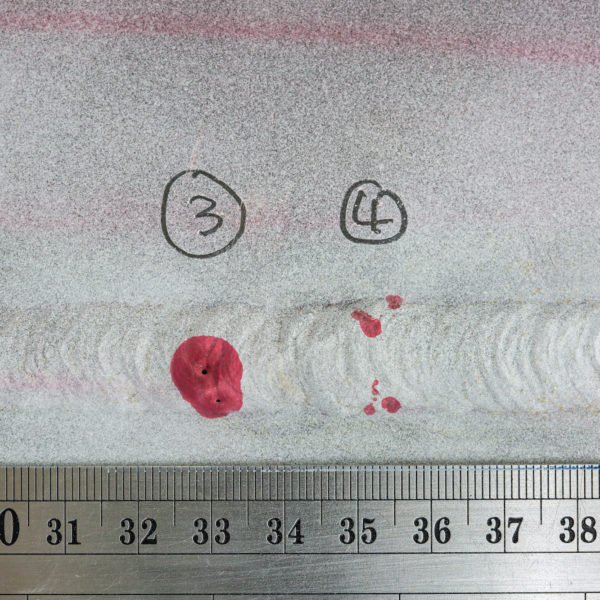

BECA utilizes Liquid Penetrant Inspection to detect surface discontinuities in both ferromagnetic and non-ferromagnetic materials. In castings and forgings, these may be cracks or leaks in new products or fatigue cracks in in-service components. We perform the test using visible red dyes under visible light conditions or fluorescent dyes under ultraviolet light. As the name implies, the dyes penetrate into the surface discontinuities by capillary action. After the excess material is removed from the material being tested, indications will appear. Evaluation and classification of material is based on code or customer requirements.