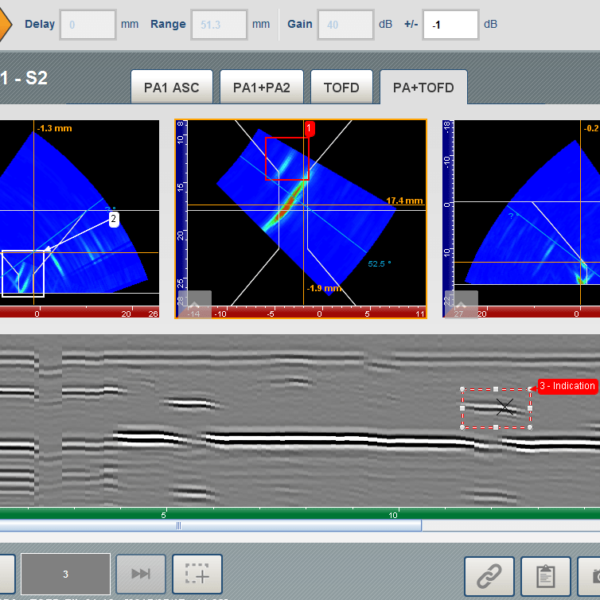

Time of Flight Diffraction (TOFD) is an advanced method of Ultrasonic inspection that leverages on existing UT methodologies thereby bringing a whole new range of testing and detection capabilities to the NDT forefront.

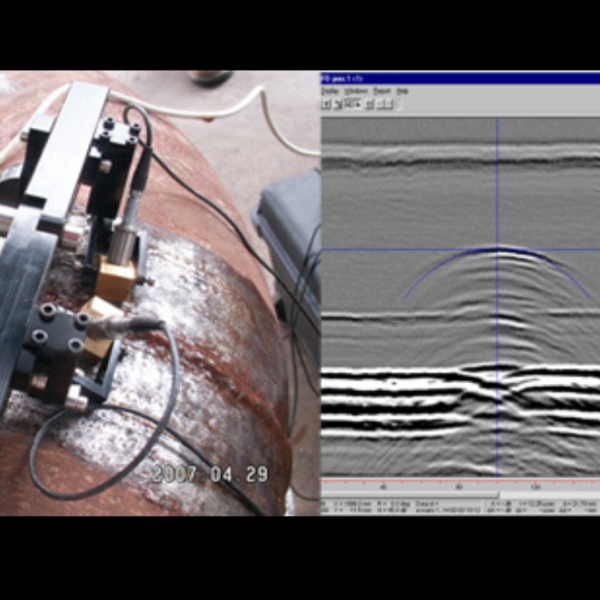

Whilst conventional ultrasonic uses shear / transverse waves as the primary mode of detection, TOFD uses longitudinal waves as the primary detection mode. Ultrasonic sensors are placed on each side of the weld. One sensor transmits the ultrasonic beam into the material and the other sensor receives both reflected and diffracted ultrasound from anomalies and geometric reflectors.

Benefits of ToFD :

- Based on diffraction, so relatively indifferent to weld bevel angles and flaw orientation

- Providing an excellent record of vessel or pipe condition at birth.

- Can also be used for in-service defects, such as cracking, corrosion, erosion, etc. Has a very high temperature limitation (700 F), with slight loss in sensitivity.

- Detects flaws regardless of their orientation within the weld.

- Can be applied without the need to shut down other activities in the area (which RT demands).

- Can be applied either during welding or immediately after completion of the weld, allowing instant determination of weld quality.

- Allows flaw growth monitoring for run/repair decisions.

- Uses time of arrival of signals received from crack tips for accurate defect positioning and sizing

- Quick to set up and perform an inspection, as a single beam offers a large area of coverage

- Rapid scanning with imaging and full data recording

- Can also be used for detecting irregularly shaped areas of metal loss during corrosion inspections