Automated Corrosion Mapping

The use of Automated Corrosion Mapping systems working with robotic scanners have been employed throughout many sectors of Industry for rapid overview of equipment condition. The Automated Corrosion Mapping systems are capable of acquiring actual wall thickness over large areas of vessels and piping while the system remains in operation.

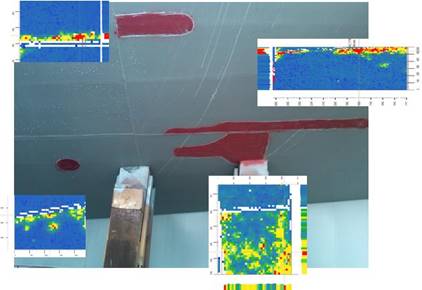

Automated Corrosion Mapping Ultrasonic scans of materials, uses a range of colors to represent the thickness range of part being inspected; typically blue colors are used to represent nominal wall thickness with orange and red colors used to indicate significant wall reduction.

Benefit of using the automated imaging systems:

- can inspect 20-30 sq. meters per standard work day

- allows a picture (C-Scan Image) quickly identifies any significant reduction in wall thickness

- The scans can be superimposed into development drawings of equipment and accurately indicate location of problem regions.

Another application for this technology is the mapping of vessels with weld overlay to evaluate the presence and or extent of dis-bonding.